Confined spaces represent some of the most hazardous work environments in industry.

Defined as areas not designed for continuous occupancy, with limited entry and exit points, they present risks that can quickly turn deadly.

Statistics indicate that around 92 worker deaths occur annually in the U.S. due to confined space accidents, highlighting the need for strict safety measures.

Proper training, adherence to regulations, and use of advanced monitoring systems help prevent such tragedies.

Regulatory frameworks such as OSHA standards in the U.S. and AS 2865 in Australia set out clear requirements, creating a structured approach to worker protection.

A proactive culture of safety must begin before anyone sets foot inside.

Table of Contents

ToggleRule #1: Conduct Hazard and Risk Assessments

Risk assessments form the foundation of safe confined space entry.

Pre-entry checks include atmospheric testing to detect:

Workers must also consider physical hazards like machinery parts, risks of engulfment in materials such as grain or sand, and structural weaknesses.

Classifying a space correctly is equally important. Permit-required confined spaces carry greater risks and demand a higher level of oversight.

Entry permits outline specific conditions, responsibilities, and authorizations, ensuring no step is overlooked.

Rule #2: Implement Control Measures

Once hazards are identified, control measures must be put in place.

Eliminating the need for entry altogether remains the safest option, achieved through automation or remote-controlled tools.

When entry cannot be avoided, isolation of the space is critical. Lockout/Tagout procedures prevent energy sources like electricity, hydraulics, or gas from creating unexpected dangers.

Additional safeguards include blocking pipes, sealing vents, and mechanically isolating machinery.

Proper ventilation is essential, with fresh air introduced using blowers and trunking.

Oxygen must never be used for purging due to the risk of fire or explosion.

In some facilities, teams pair these practices with services such as baler service to streamline safe operations while maintaining equipment standards.

Rule #3: Atmospheric Testing and Monitoring

Atmospheric hazards are often invisible, making testing a non-negotiable requirement.

Pre-entry monitoring establishes baseline conditions, while continuous monitoring ensures ongoing safety.

Instruments such as electrochemical sensors, infrared detectors, and multi-gas monitors detect the following aspects:

Best practices involve layering monitoring systems.

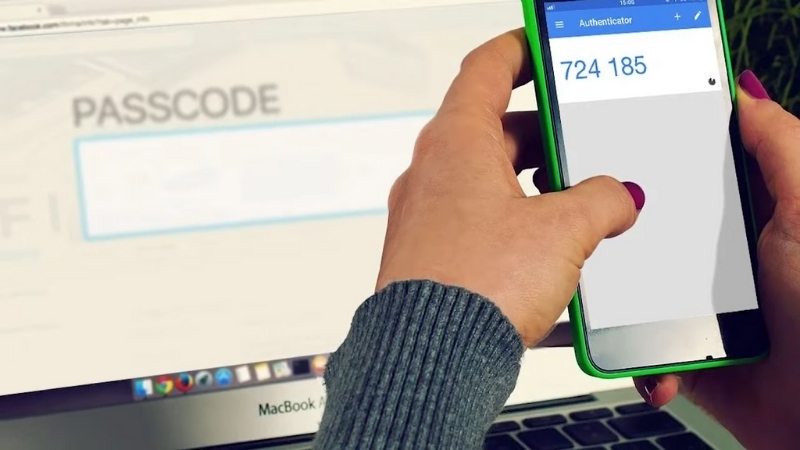

Personal detectors alert individuals immediately, while area monitors provide broader coverage.

Connected devices offer real-time data to safety teams outside the space, improving response times.

Using sampling pumps extends reach into confined areas before entry, ensuring workers know conditions inside without taking unnecessary risks.

Monitoring technology has advanced significantly, giving workers vital protection in hazardous spaces.

Rule #4: Ensure Proper Use of PPE and Safety Equipment

Protective gear is a lifeline for workers entering confined spaces. Standard equipment includes fire-resistant clothing, steel-toe boots, gloves, and helmets designed to resist impacts.

Fall protection systems such as harnesses, lifelines, and anchoring points prevent severe injuries in vertical entries.

Depending on the risk, workers may require supplied-air respirators or SCBAs (self-contained breathing apparatus).

Emergency escape devices ensure rapid exit if conditions deteriorate. PPE must be inspected, maintained, and fitted correctly for each worker.

Training in the use of equipment ensures not only compliance but also confidence during critical operations. Neglecting PPE is never an option when lives are at stake.

Rule #5: Assign a Standby Attendant and Maintain Communication

Safe confined space entry requires the presence of a standby attendant, also known as a hole watch or safety observer.

Positioned outside the confined space, this individual plays a critical role in safeguarding workers inside.

Their responsibilities go far beyond simply standing by.

They must maintain constant observation, record ongoing conditions, and coordinate responses if hazards emerge.

Entering the space themselves is never permitted unless they have received advanced training and are fully equipped for a rescue scenario.

An effective attendant must also master multiple methods of communication.

Depending on the environment, noise levels, and available equipment, communication may take several forms.

By announcing the primary tools of communication, workers can prepare themselves to respond appropriately in real-time:

The reliability of communication systems can make the difference between a safe outcome and a disaster. Workers inside must be able to report hazards instantly, while the attendant must be prepared to order evacuation if conditions deteriorate.

The human oversight provided by an attendant, combined with dependable communication, creates a safety net that reduces risks and ensures immediate action when needed.

Rule #6: Emergency Preparedness and Rescue Planning

Preparation for emergencies separates well-managed confined space operations from those that end in tragedy.

Every job site should have a plan tailored to the specific hazards present.

Fires, toxic atmospheres, structural instability, and medical emergencies must all be anticipated in advance.

A well-structured emergency plan outlines who responds, what equipment is used, and how workers are evacuated safely.

Rescue protocols should never be improvised. Proper equipment, first aid kits, and fire extinguishers must be readily available.

Just as importantly, personnel must be trained not only in entry but also in safe rescue.

Muscle memory developed through drills ensures that workers respond instinctively in high-stress situations.

To reinforce preparation, organizations should announce and adopt several critical practices:

Investment in training and rescue planning demonstrates commitment to worker safety.

Employers who prioritize readiness not only comply with regulations but also reinforce a culture of responsibility.

Workers entering confined spaces must have the assurance that if something goes wrong, rescue will be swift, coordinated, and effective.

Rule #7: Training and Competency

@cyccaccessConfine space rescue training on 4:1 rescue♬ original sound – CYCC Access Systems

No safety rule matters unless workers are trained to apply it. Training should cover confined space entry procedures, hazard recognition, use of monitoring devices, and rescue strategies.

Employees must learn to operate gas detectors, respirators, and communication systems effectively.

Competency does not stop at initial training. Periodic reassessments and refreshers keep skills sharp and reinforce correct practices.

Tabletop exercises simulate planning stages, while practical drills replicate real hazards.

Organizations that emphasize ongoing competency instill a mindset where safety becomes second nature.

In such an environment, workers are prepared for both routine tasks and unforeseen dangers.

Summary

Confined space entry requires a disciplined and structured approach built around seven core rules.

Hazard assessments, control measures, atmospheric monitoring, PPE use, attendants, emergency plans, and ongoing training work together to safeguard workers.

Industrial teams that commit to proactive safety practices reduce risks dramatically. Continuous improvement, integration of new technology, and adherence to regulations ensure compliance while reinforcing a culture of care.

Worker lives depend on vigilance, making confined space safety not just a rulebook but a shared responsibility.